Plastic Sheet Extrusion Production Line

Basic Info

Model No.: sj90/30

Product Description

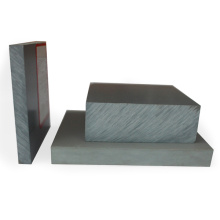

Model NO.: sj90/30 Condition: New Customized: Customized Power Source: Electric Product Type: Plastic Sheet Rotation Speed: 80r/Min Thickness: 1.5~2.5mm Extrusion Material: PP Trademark: suke Origin: Qingdao, China Certification: SGS, CE, ISO Screw Design: Single-Screw Application: Sheet Automatic Grade: Automatic Diameter: 90mm Output Capacity: 200kg/H Width: 600mm L/D: 33:1 Specification: ISO9001 CE HS Code: 84775900 Plastic Sheet Extrusion Production Line

Automatic feeder:

Series hopper dryers are designed for drying non-hygroscopic plastics granules series blows hot air from bottom cone via a shade separator. Standard features include P.D. temperature control (drying up to 150ºC), hinged hopper for easy cleaning, hopper base assembly, hopper lid prepared for easymounting of hopper loader. Options include 24-hr timer, insulated hopper, dust collector,hot air recycler, take-off box, mobile stand etc.

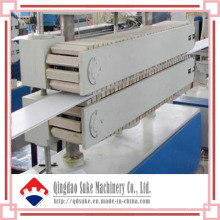

Three roller Frame:

It can rise or down, and moving front or back by electrically adjust. There is circulating oil in per roll. Each roller heated and controlled separately.

Optional Auxiliary Machines:

1. Hydraulic Screen Exchanger

2. Mixer

3. Crusher,

Detailed specification of the line:

The price is a reference price, we will pricing it with your demand if you contact us.

Contact us if you need more details on Sheet Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sheet Production Line、Plastic Sheet Extrusion Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Automatic feeder:

Series hopper dryers are designed for drying non-hygroscopic plastics granules series blows hot air from bottom cone via a shade separator. Standard features include P.D. temperature control (drying up to 150ºC), hinged hopper for easy cleaning, hopper base assembly, hopper lid prepared for easymounting of hopper loader. Options include 24-hr timer, insulated hopper, dust collector,hot air recycler, take-off box, mobile stand etc.

Three roller Frame:

It can rise or down, and moving front or back by electrically adjust. There is circulating oil in per roll. Each roller heated and controlled separately.

Optional Auxiliary Machines:

1. Hydraulic Screen Exchanger

2. Mixer

3. Crusher,

Detailed specification of the line:

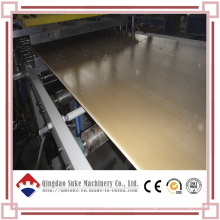

| PP/PE/PS/ABS Sheet machine, PP sheet making machine, PS sheet production machine, PE sheet extrusion machine, ABS Sheet Production Line | ||

| Single Screw Extruder | adopts long L/D, high efficiency screw, high extrusion capacity, uniformed plasticization. Extruder and haul off machine motors adopt imported AC/DC inverter as speed regulators. | |

| Vacuum Feeding Machine | Feeding Capaity: Max 350kg/h | |

| T-type Die Head | Die Head Material: 5CrNiMo Brands: JC-times,. | |

| Three Roller Calendar | Motor power: 1.1kw*3 sets, with ABB frequency inverter Roller Diamter: 350-450mm, Roller Wall thickness: 35mm | |

| Cooling Frame and Edge Trimming Unit | Cooling Frame length: 6000mm Edge trimming: 2 knives, position adjustable | |

| Hual off Machine | Haul off method: 2-rubber rollers Motor: 3kw with ABB inverter | |

| Cutting machine | Guillotine-knife cutting machine or Twin position Coiler | |

| Electrical cabinet: | ABB inverter, Shneider contator, RKC thermocontroller, Siemens PLC, and etc. | |

Contact us if you need more details on Sheet Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sheet Production Line、Plastic Sheet Extrusion Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Sheet Machine

Premium Related Products

Other Products

Hot Products

2014 twin-screw extrusion machinePC Sheet Making Machine / Production Line For Making Multi- Function Sheet (Plastic Machine)Product Thickness 0.2-1.0mm CE Certificate Aggricultural Plastic Flat Pipe MachinePOLYTECH Round Dripper Flexible Inlet Irrigation Pipe Extrusion Making MachineLabyrinth Strip Embedded Drip Irrigation Pipe Extrusion LineLow Invest /Stable Output UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line2014 singal wall corrugated pipe extrusion line /PE PP PA plastic corrugated pipe extrusion linePPR/HDPE Plastic Pipe Extrusion Line / Multi-Function Plastic Pipe Extrusion Machine2014 Higher Quality Construction Formwork Production Line/8~25mm Thickness PE Plastic Construction Formwork Making MachineISO CE Standard PVC Plastic Twin-Wall Hollow Roofing Sheet Co-Extrusion Production Line /MachineWPC/PVC Foam Board Plastic Machine /WPC Foam Sheet Line PVC Plastic Foam Board Extrusion MachineWPC Foamed Board Plastic MachineISO CE Standard PVC Glazed Tile Palstic Machine ,PVC Plastic Tile Production Line For ExportedWindow and Door frame Making Machine /PVC Window Profile Extrusion Machine /Production Line /Plastic ExtruderAlibaba PE WPC profile extrusion machine for pavilion,dustbin,fence,floor boardPlastic roofing sheet extruding machine for make PE PP recycled roof