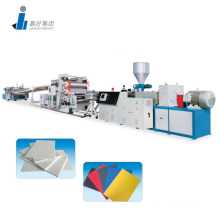

WPC/PVC Foam Board Plastic Machine /WPC Foam Sheet Line PVC Plastic Foam Board Extrusion Machine

Basic Info

Model No.: SJZS80/92SJZS80/92/65

Product Description

WPC/PVC Foam Board Plastic Machine /WPC Foam Sheet Line PVC Plastic Foam Board Extrusion Machine  1. Two conical screw extruders keep a high output for the co-extrusion, when you want to make one layer board, only stop one extruder

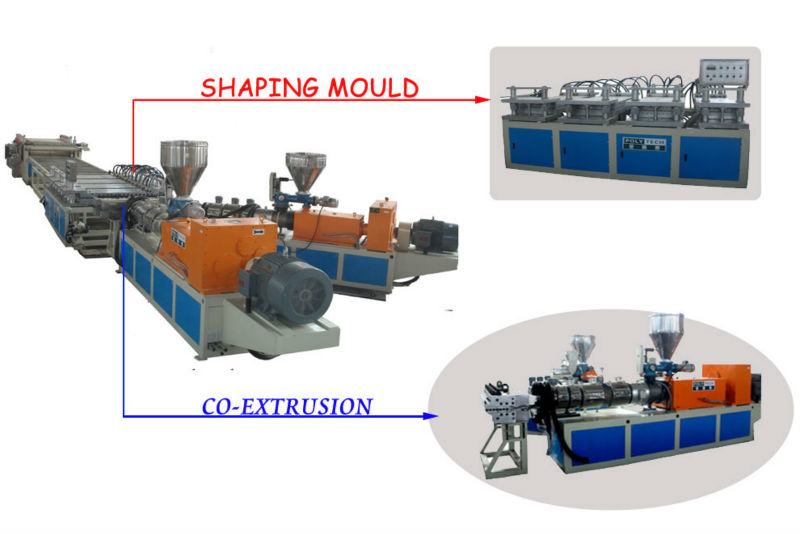

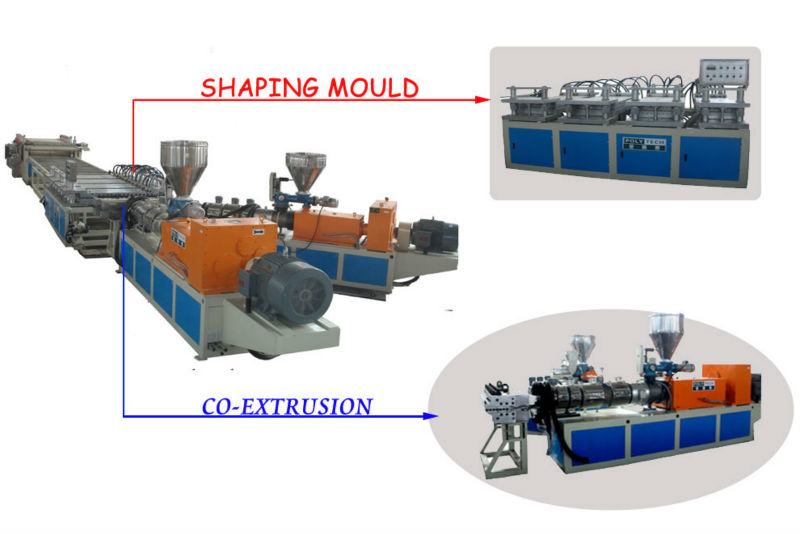

1. Two conical screw extruders keep a high output for the co-extrusion, when you want to make one layer board, only stop one extruder

2. T-die and distributor make the processing evenly (thickness is adjustable)

3. Shaping mould keep a good shape and high precision of the finished WPC foamed board

4. Cooling trial with two side blade cutting for the thinner sheet

5. Laminating device

6. Haul-off device with normal 8 rubber roller groups and two side saw cutting for thicker board

7. The auto saw cutter the dust collection device

8. Stacker Specifications:

Applications:

WPC/PVC Foam Board Plastic Machine /WPC Foam Sheet Line PVC Plastic Foam Board Extrusion Machine mainly used in the production of wood-plastic foamed board.

The wood-plastic foamed board has the advantages of both wood and plastic. It not only has the excellent appearance of the natural wood, but also overcomes the disadvantages of the natural wood. With the advantages of anti-corrosion, moisture-proof, anti-moth-eaten, dimensional-steady, no cracking, etc, it is much harder than the pure plastic products and has the similar process-ability as the wood. It can be cut, paint, bonded and fixed with nails or bolts. As the wood-plastic board material has the advantages of low price and excellent performance. Competitive Advantage: We focus on the co-extrusion technology which keep high output and overcome many operating problems for the one layer board;

Competitive Advantage: We focus on the co-extrusion technology which keep high output and overcome many operating problems for the one layer board;  Our Services Our services: 1 MACHINE DESIGN 2 MACHINE PROCESSING 3 MACHINE TESTING 4 MACHINE DELIVERY 5 TOTAL SOLUTION FOR MACHINE AFTER-SERVICE

Our Services Our services: 1 MACHINE DESIGN 2 MACHINE PROCESSING 3 MACHINE TESTING 4 MACHINE DELIVERY 5 TOTAL SOLUTION FOR MACHINE AFTER-SERVICE

Company Information Company information: For the past 25 years, we have sold our machine lines to more than 30 countires with 800 lines. With the help from our representatives in different areas, we would like to introduce and cooperate with more strong and potential customers. POLYTECH would like to company with you, developing with you, support with you. All of us go togther to make another good record for the plastic extrusion industry.  Fair information:

Fair information:

Contact us if you need more details on Foam Board Plastic Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wpc Foam Sheet Extrusion Machine、Wpc Board Plastic Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Two conical screw extruders keep a high output for the co-extrusion, when you want to make one layer board, only stop one extruder

1. Two conical screw extruders keep a high output for the co-extrusion, when you want to make one layer board, only stop one extruder2. T-die and distributor make the processing evenly (thickness is adjustable)

3. Shaping mould keep a good shape and high precision of the finished WPC foamed board

4. Cooling trial with two side blade cutting for the thinner sheet

5. Laminating device

6. Haul-off device with normal 8 rubber roller groups and two side saw cutting for thicker board

7. The auto saw cutter the dust collection device

8. Stacker Specifications:

Main extruder | SJZS-80/ SJZS-65 | SJZS-92/ SJZS-80 |

Width of finished product | 915mm,1220mm | 915mm,1220mm |

Thickness of finished product | (5-25)mm | (5-25)mm |

Max output | 400kg/h | 800kg/h |

Drive motor | 55kw,37 kw | 110kw,55kw |

Applications:

WPC/PVC Foam Board Plastic Machine /WPC Foam Sheet Line PVC Plastic Foam Board Extrusion Machine mainly used in the production of wood-plastic foamed board.

The wood-plastic foamed board has the advantages of both wood and plastic. It not only has the excellent appearance of the natural wood, but also overcomes the disadvantages of the natural wood. With the advantages of anti-corrosion, moisture-proof, anti-moth-eaten, dimensional-steady, no cracking, etc, it is much harder than the pure plastic products and has the similar process-ability as the wood. It can be cut, paint, bonded and fixed with nails or bolts. As the wood-plastic board material has the advantages of low price and excellent performance.

Competitive Advantage: We focus on the co-extrusion technology which keep high output and overcome many operating problems for the one layer board;

Competitive Advantage: We focus on the co-extrusion technology which keep high output and overcome many operating problems for the one layer board;  Our Services Our services: 1 MACHINE DESIGN 2 MACHINE PROCESSING 3 MACHINE TESTING 4 MACHINE DELIVERY 5 TOTAL SOLUTION FOR MACHINE AFTER-SERVICE

Our Services Our services: 1 MACHINE DESIGN 2 MACHINE PROCESSING 3 MACHINE TESTING 4 MACHINE DELIVERY 5 TOTAL SOLUTION FOR MACHINE AFTER-SERVICE |

|

Fair information:

Fair information:  |

Product Categories : Plastic Board Extrusion Line > PVC Foamed Board Extrusion Line

Premium Related Products

Other Products

Hot Products

2014 twin-screw extrusion machinePC Sheet Making Machine / Production Line For Making Multi- Function Sheet (Plastic Machine)Product Thickness 0.2-1.0mm CE Certificate Aggricultural Plastic Flat Pipe MachinePOLYTECH Round Dripper Flexible Inlet Irrigation Pipe Extrusion Making MachineLabyrinth Strip Embedded Drip Irrigation Pipe Extrusion LineLow Invest /Stable Output UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line2014 singal wall corrugated pipe extrusion line /PE PP PA plastic corrugated pipe extrusion linePPR/HDPE Plastic Pipe Extrusion Line / Multi-Function Plastic Pipe Extrusion Machine2014 Higher Quality Construction Formwork Production Line/8~25mm Thickness PE Plastic Construction Formwork Making MachineISO CE Standard PVC Plastic Twin-Wall Hollow Roofing Sheet Co-Extrusion Production Line /MachineWPC/PVC Foam Board Plastic Machine /WPC Foam Sheet Line PVC Plastic Foam Board Extrusion MachineWPC Foamed Board Plastic MachineISO CE Standard PVC Glazed Tile Palstic Machine ,PVC Plastic Tile Production Line For ExportedWindow and Door frame Making Machine /PVC Window Profile Extrusion Machine /Production Line /Plastic ExtruderAlibaba PE WPC profile extrusion machine for pavilion,dustbin,fence,floor boardPlastic roofing sheet extruding machine for make PE PP recycled roof