Pet PP Strap Band Production Line

Basic Info

Model No.: SK Series

Product Description

Model NO.: SK Series Plastic Processed: PP Feeding Mode: One Feed Screw: Twin-Screw Screw Channel Structure: Deep Screw Automation: Automatic Power Supply: 380V Three Phase Inverter: ABB Warranty: 12monthes Extruder Model: Single Screw Extruder Raw Materal: Pet/PP Trademark: Suke Specification: CE ISO9001 HS Code: 84775900 Type: PP Pet Strap Band Product Type: Granulating Extruder Assembly Structure: Integral Type Extruder Engagement System: Full Intermeshing Exhaust: Exhaust Computerized: Computerized Control System: PLC Temperature Controller: Omron F Machine Color: as Request Contactor: Siemens Cooling Method: by Water Transport Package: According to Your Requirement Origin: Qingdao China Pet PP Strap Band Production Line

Introduction of Pet, PP Strap Band Production Line (Suke Series):

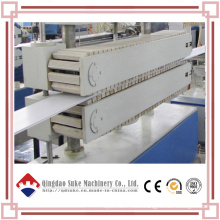

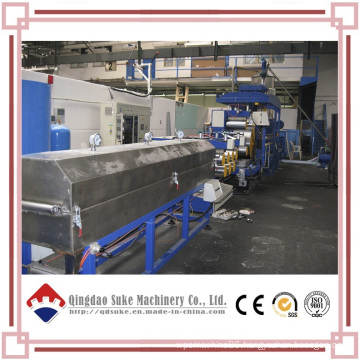

PP strapping band production line is mainly composed of: Single screw extruder with automatic feeding drying syste, , mould for strap band, water tank, first haul off, stretching oven, second haul off, embossing, printing, second stretching oven, sizing water tank, dryer, third haul off, winder. There are mainly two models: 60kg/h and 100-120kg/h

Main features of PP strap band production line:

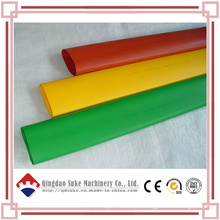

Recycled PP can be used

High tension drawing force

The pp strap bands are uniformity in width, precise shape and size can be applied in full automatic strapping machine

With full automatic temperature controling system and automatic alarming system,

Advanced technique makes the product with lower cost.

Low power consumption, low noise

If you want more details about this production line please contact us

TRADE TERMS Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable Delivery Time: 40 days after receipt of prepayment. Packing Method: Packing film or wooden case Guaranteed Time: 12 months

MACHINERUNNING TEST AND AFTER SERVICE When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container. When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable. If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24 hours. Contact us if you need more details on Pet Strap Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PP Strap Production Line、Pet Band Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Introduction of Pet, PP Strap Band Production Line (Suke Series):

PP strapping band production line is mainly composed of: Single screw extruder with automatic feeding drying syste, , mould for strap band, water tank, first haul off, stretching oven, second haul off, embossing, printing, second stretching oven, sizing water tank, dryer, third haul off, winder. There are mainly two models: 60kg/h and 100-120kg/h

Main features of PP strap band production line:

Recycled PP can be used

High tension drawing force

The pp strap bands are uniformity in width, precise shape and size can be applied in full automatic strapping machine

With full automatic temperature controling system and automatic alarming system,

Advanced technique makes the product with lower cost.

Low power consumption, low noise

If you want more details about this production line please contact us

| No. | Item | Qty |

| 1 | Vacuum autoloader | 1pc |

| 2 | PET dryness system | 1pc |

| 3 | Single screw extruder | 1pc |

| 4 | Die head | 1pc |

| 5 | Water trough calibration system | 1pc |

| 6 | First pre-heating machine | 1pc |

| 7 | Short wave infrared ray heating oven | 1pc |

| 8 | First tensile pre-heating machine | 1pc |

| 9 | Short wave infrared ray heating oven | 1pc |

| 10 | Second tensile machine | 1pc |

| 11 | Embossing machine | 1pc |

| 12 | Three rollers cooling machine | 1pc |

| 13 | Tight hot calibration machine | 1pc |

| 14 | Third haul-off | 1pc |

| 15 | Double winder | 2pcs |

| 16 | SML Chillier | 1pc |

| MKS-A mould Temperature controller | 2sets |

TRADE TERMS Payment Term: 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable Delivery Time: 40 days after receipt of prepayment. Packing Method: Packing film or wooden case Guaranteed Time: 12 months

MACHINERUNNING TEST AND AFTER SERVICE When machine finished, we will invited client come to our factory to check the machine and do the machine test. If machine is ok, then client pay for the balance. And inspect machine load the container. When machine arrives client's factory, if client needs, we will send 1-2 engineer to client's factory do the machine installation and running test, and also train the local worker how to operate and maintain the machine. It is chargeable. If have any question or problem on machine operation or maintain, welcome to contact to us by email or calling. We stand by 24 hours. Contact us if you need more details on Pet Strap Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PP Strap Production Line、Pet Band Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic PET/PP Strap Band Machine

Premium Related Products

Other Products

Hot Products

2014 twin-screw extrusion machinePC Sheet Making Machine / Production Line For Making Multi- Function Sheet (Plastic Machine)Product Thickness 0.2-1.0mm CE Certificate Aggricultural Plastic Flat Pipe MachinePOLYTECH Round Dripper Flexible Inlet Irrigation Pipe Extrusion Making MachineLabyrinth Strip Embedded Drip Irrigation Pipe Extrusion LineLow Invest /Stable Output UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line2014 singal wall corrugated pipe extrusion line /PE PP PA plastic corrugated pipe extrusion linePPR/HDPE Plastic Pipe Extrusion Line / Multi-Function Plastic Pipe Extrusion Machine2014 Higher Quality Construction Formwork Production Line/8~25mm Thickness PE Plastic Construction Formwork Making MachineISO CE Standard PVC Plastic Twin-Wall Hollow Roofing Sheet Co-Extrusion Production Line /MachineWPC/PVC Foam Board Plastic Machine /WPC Foam Sheet Line PVC Plastic Foam Board Extrusion MachineWPC Foamed Board Plastic MachineISO CE Standard PVC Glazed Tile Palstic Machine ,PVC Plastic Tile Production Line For ExportedWindow and Door frame Making Machine /PVC Window Profile Extrusion Machine /Production Line /Plastic ExtruderAlibaba PE WPC profile extrusion machine for pavilion,dustbin,fence,floor boardPlastic roofing sheet extruding machine for make PE PP recycled roof